INDUSTRIAL INSULATION SUPPLIER

Constructing and maintaining an industrial insulation application presents many challenges. Each decision directly influences efficiency, safety, and long-term performance, especially when it comes to insulation. The right insulation materials provide optimal thermal, acoustic, and fire protection performance for every application, including mechanical insulation systems.

Founded in 1982, Specialty Products and Insulation (SPI) offers an extensive inventory of insulation products for industrial applications. Our experts understand the demands of your industry and are ready to help you get the ideal solutions for your projects. Today, SPI is a world leader in insulation fabrication and distribution with a global footprint within the insulation industry. We can leverage our network of over 100 fabrication and distribution locations around the world in Australia, Canada, and the United State, as well as a dedicated international projects team.

Partner with SPI to Address Common Industrial Challenges

We work alongside industrial insulation contractors to deliver solutions for complex industrial projects. As both a fabricator and distributor, we provide insulation solutions to help you address various challenges.

.jpg)

![]()

.Temperature Control

Maintaining temperatures in industrial facilities is crucial for process efficiency and equipment longevity. Our thermal insulation solutions can improve thermal stability across a wide range of temperature applications. We also understand how in industrial insulation, the external environment can be just as important when selecting the combination of materials for your application. SPI is here to serve as your unbiased partner and can walk you through the pros and cons of any materials for your specific project or application.

![]()

Freeze Protection

The right insulation solution can provide freeze protection at industrial facilities by reducing heat loss from pipes, valves, and equipment exposed to harsh cold environments outdoors. By maintaining above-freezing temperatures, insulation helps prevent water, chemicals, or other process fluids from freezing, which can block flow or rupture pipes. Proper insulation systems can prevent cracked or burst lines, which result in costly repairs, shutdowns, or even environmental hazards. Our solutions can help ensure your systems run smoothly during winter, minimizing downtime and maintaining productivity.

![]()

Corrosion Under Insulation

Proper insulation selection reduces the risk of corrosion under insulation (CUI), supporting the longevity of industrial equipment. CUI occurs most often at operating temperatures between 100°F and 350°F (38°C – 177°C), in the presence of oxygen, liquid water, or corrosive chemical components, and when PH levels drop below seven (7).

Some of the points in an insulation system that can be vulnerable to CUI include elbows, irregular shapes like valves and accessories, any jacket penetration and termination locations, as well as any locations for potential hydrocarbon leakage (e.g. low-points, flanges, valves, and couplings). SPI can partner with you to identify the best possible insulation products to prevent CUI-related issues, including accessories such as drain plugs, access plug flanges, and joint sealant. We also encourage implementing consistent inspection and maintenance practices on site.

![]()

Excessive Noise and Vibration

Industrial environments require noise reduction solutions to increase safety and operational efficiency. Many of our insulation materials can minimize sound transmission and vibration, creating a more controlled environment.

![]()

Personnel Protection

Industrial insulation solutions can support and protect personnel on industrial sites in a multitude of ways. These include:

- Preventing burns or other heat-related injuries through thermal protection

- Reducing the risk of slips and falls by preventing condensation

- Lowering the risk of hearing damage with acoustic insulation

- Fire safety with the application of fire-resistant materials that will slow the spread of fire, giving personnel more time to evacuate

![]()

Compliance With Regulations and Safety Standards

Meeting industry regulations requires insulation that aligns with strict safety and performance criteria. Proper insulation in an industrial setting can improve personnel protection by reducing the risk of burns and injuries, minimizing fire spread, and protecting equipment from damage.

![]()

Fire Protection

Industrial facilities benefit from insulation materials that enhance fire safety. We offer fire-rated solutions designed to protect equipment and structures as well as limiting the spread of fire and smoke, preventing injuries and reducing damage to valuable equipment. As your partner in insulation, we can walk you through which products would offer the best fire protection for your application.

![]()

Reducing Emissions and Energy Costs

Reducing energy consumption remains a priority in industrial settings. Our insulation solutions improve energy efficiency by minimizing heat loss and optimizing thermal control.

SPI's Wide Range of High-Performance Industrial Insulation Materials

Industrial facilities require insulation that withstands diverse conditions. With 130,000+ SKUs and over 1,000 vendor partners, SPI offers materials suited for various temperature applications, from cryogenic to high-temperature refractory insulation. Our solutions for industrial insulation applications provide optimal thermal control, durability, and efficiency. More than just a supplier, SPI is here to be your partner in insulation, providing an unbiased perspective when selecting the right product to meet the insulation needs of your specific project. These are some of the most popular industrial insulation materials we supply broken down by insulation type.

Fibrous Insulation Materials

Ceramic Fiber

Ceramic fiber insulation withstands extremely high temperatures while offering low thermal conductivity. Its lightweight composition provides flexibility for applications requiring high heat resistance. Ceramic fiber insulation can also be used as an alternative to calcium silicate and mineral wool. It is available in several different forms including blankets and boards. Ceramic Fiber is also offered in a variety of thicknesses and is also offered in paper and tape. Often referred to as a “refractory material,” common industrial insulation applications include industrial furnaces and kilns, pipes, fire protection systems, and furnace and boiler linings.

Mineral Wool

Mineral wool insulation is a high-density material that is durable and long-lasting. Its properties include excellent thermal performance, water resistance, sound and vibration control, an upper temperature limit of 650°C/1200°F, non-combustible, and easy to ship, fabricate and install. Mineral wool is available in many forms, including mandrel wound pipe sections, v-groove, wraps, boards, and fabricated fittings. It is an optimum choice for several industrial applications including process piping and equipment, tanks, vessels, industrial boilers, and columns.

Cellular Insulation Materials

Cellular Glass

Cellular glass insulation delivers strong resistance to moisture and fire. Cellular glass is a unique insulation that offers long-term performance in extreme environments. Cellular glass insulation is a lightweight, rigid material composed of millions of completely sealed glass cells. Some of the reasons for choosing cellular glass for your industrial application include:

- Excellent Temperature Range -268°C to 468°C

- Non-combustible

- Impermeable to water and water vapor

- Non-wicking

- Corrosion and chemical resistant

- Long-term dimensional stability

- High compressive strength

Cellular glass is available in many forms, including pipe sections, blocks, curved segments, fittings (elbows, reducers, tees), pre-formed vessel head segments, and pre-formed segments for spherical tanks. Common industrial applications for cellular glass include cryogenic systems, low temperature pipe, medium temperature pipe, hot oil and asphalt storage tanks, heat transfer fluid systems, hydrocarbon process systems, steam and chilled water piping, direct burial, tank dressing, and tank bases.

Polyisocyanurate

This rigid foam insulation is a cost-effective material that provides excellent thermal resistance while maintaining structural integrity. It is frequently used in low-temperature applications requiring moisture resistance. Some of the reasons our customers choose polyisocyanurate (also commonly referred to as "polyiso") include:

- Moisture resistance

- Lightweight material

- Easy installation

- Good compressive resistance

Available forms include pipe sections, boards, curved segments, and fabricated fittings. Common industrial applications for polyiso include cold storage, below grade applications, pipes, HVAC, and building roofs and walls.

Granular Insulation Materials

Calcium Silicate

Designed for high-temperature environments, calcium silicate insulation offers durability and resistance to moisture and maintains thermal efficiency under demanding conditions. Some of the reasons for selecting calcium silicate for your next industrial insulation project include:

- Excellent thermal performance

- Excellent compressive strength >100psi/690kPa

- Pass Fire Protection UL-1709 – 60mins

- Upper temperature limits to 650°C/1200°F

- Water resistance

- Corrosion inhibitor

Calcium silicate is available in many forms, including pipe sections, curved sidewall sections, 3V scored boards, block/boards, and fabricated fittings. Common industrial applications include process piping and equipment, industrial exhaust systems, vessels, tanks, columns as well as any high traffic areas or where elevated temperatures are as high as 650ºC/1200ºF.

Perlite

Perlite insulation is a cost-effective choice for cryogenic and high-temperature applications where exposure to moisture is common. It is non-combustible and resistant to corrosion under insulation. Perlite’s lightweight structure and thermal stability make it suitable for industrial piping and equipment up to temperatures of 650°C/1200°F. It is also resistant to absorption or oil and water.

Perlite insulation is available in a variety of forms including blocks, pipe sections, fabricated fittings, and curved segments. Common industrial applications for perlite include high temperature piping and equipment, industrial processing and power generation, as well as cryogenic applications.

Thin Profile Blanket Insulation

Thin profile insulation blankets allow insulators to protect piping and equipment when little space is available. Thin blankets are incredibly versatile and provide excellent protection against heat loss or gain and offer a great option for Cryogenic applications as well. Available using several different technologies, such as aerogel, and thin blanket insulation is often selected as an industrial insulation solution for a variety of reasons, including:

- Versatile Temperature range. Up to 650°C/1200°F

- Non-combustible

- Hydrophobic

- Excellent Thermal protection even if compressed.

- Corrosion/chemical resistant

- Easily Fabricated and economically shipped

Available forms of blanket insulation include pipe sections, curved segments, blocks, fittings (e.g. elbows, reducers, and tees), pre-formed vessel head segments, pre-formed segments for spherical tanks. Common applications include cryogenic systems (LNG), low, medium and high temperature piping and equipment, fireproofing, pipelines, and areas where CUI is a concern.

Metal Insulation Jacketing

All industrial insulation systems require a jacket for protection against the elements, mechanical damage, chemicals and other agents that can harm the insulation system, rendering it less effective. Typical metal jacketing products consist of aluminum or stainless steel. These products can be furnished with moisture barriers on the inside to assist in the mitigation of CUI or coated with clear acrylic or painted – for extra UV and caustic protection. SPI offers jacketing cut to length, in rolls, corrugated sheets, box rib sheet, vessel heads, and elbows or sweeps. Some of the most common industrial applications for insulation jacketing include process piping, equipment, vessels, fire rated systems, caustic areas, sound and vibration, pipelines, and ducting.

Master Fabricators for Industrial Applications

SPI provides custom fabrication services to meet the specific needs of your facility. Our fabrication team will work closely with you to deliver custom installation solutions, ensuring each component fits perfectly and performs optimally. Our fabrication capabilities deliver both quality and value to your project. Explore some of our most popular fabricated products for industrial applications.

Fabricated Tank and Vessel HATS®

These precision-engineered insulation segments are designed for tank and vessel applications to improve process operating efficiencies and reduce life cycle operating and maintenance costs. SPI has supplied prefabricated equipment and vessel head insulation for numerous LNG projects worldwide. Our superior vessel head insulation systems obtain a fit-form function that is difficult to achieve with field fabrication, while reducing labor costs and improving project schedules.

Tank and Vessel Curved Sidewall Segments

These segments are custom fabricated to precisely fit the curvature of tanks and vessels, providing optimal thermal insulation. SPI can create these segments using a range of materials, including Cellular glass, Polyisocyanurate and Extruded Polystyrene Foam, Perlite, Cal-sil, and more, to suit specific temperature requirements and application needs.

These segments ensure consistent thermal performance across the entire surface of the tank or vessel, contributing to energy savings and process efficiency.

Fabricated Pipe Supports

We offer custom pipe support solutions for enhanced thermal efficiency and structural stability, meeting specific application conditions in a variety of insulation materials, densities, and thicknesses. We also supply jacketing with matching saddles to optimize system performance and longevity.

RigidFlex® and RigidFlex® 1000 Pipe and Tank

These semi-rigid wraps are engineered for flexible, high-performance industrial applications. Made with leading manufacturer insulation materials laminated to industry-standard FSK, ASJ, and other facings. The finished roll material is used on large-diameter pipes, tanks, and vessels in lieu of preformed pipe and machine-curved segmental insulation. This reduces the typically long lead times associated with large-diameter preformed pipe insulation. Supplied in fiberglass and mineral wool insulation at densities and thicknesses to meet operating temperature requirements and conditions.

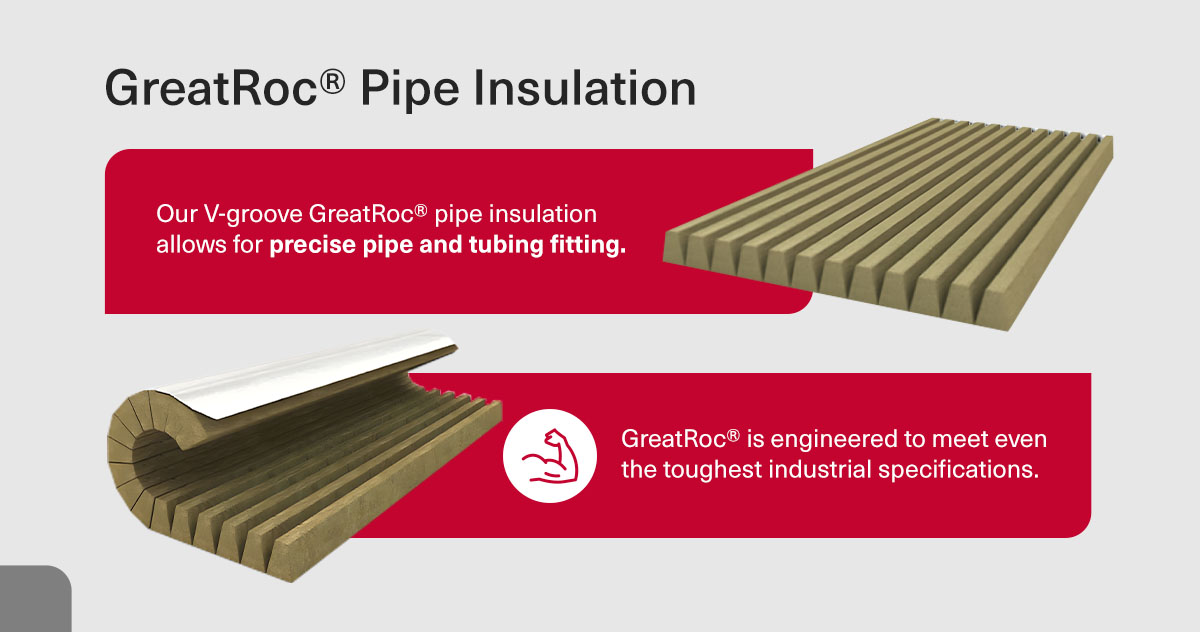

GreatRoc® V-Grooved Pipe Insulation

SPI’s GreatRoc® pipe insulation is a V-Grooved, nominal 8-pound density, half cylinder pipe insulation fabricated from Mineral Wool and is provided in Pre-Cut, Pre-Formed and Field Pre-Formed versions. It is designed for precise fit and superior insulation efficiency. GreatRoc® pipe insulation is commonly used in pipeline projects and other applications where pipes exceed 16 inches in diameter. Our customers choose GreatRoc® pipe insulation for its ability to pack flat, reducing wasted freight space by as much as 70%, significantly reducing overall freight costs.

Removable Insulation Jackets

We offer custom removable insulation solutions for equipment requiring routine maintenance. Our Removable Insulation Jackets are all field measured and custom fabricated to fit over any existing pump, flange, valve, or specialty instrument.

Cut to Measure Jacketing and Cladding Materials

SPI offers jacketing and cladding materials cut to your exact specifications, ensuring a precise fit and optimal protection for your insulation systems. These materials act as a shield against physical damage, UV exposure, corrosive elements, and moisture to extend the life span of your insulation and underlying assets.

Choose from a variety of materials, including PVC, aluminum, stainless steel, and galvalume, to meet the specific needs of your industrial application.

A Variety of Additional Insulation Solutions Available

SPI provides a selection of insulation solutions to meet the needs of various industrial applications, including:

- Acoustic products

- Fire protection products and systems

- High-temperature application solutions

- Jacketing and fittings

- Low-temperature application solutions

- Refractory products

- Safety products, PPE, and consumables

- Vapor stops and sealants

- Additional insulation accessories such as adhesives, tapes, and coatings

The Difference in Specialty Products and Insulation

SPI stands apart from other industrial insulation suppliers in several ways, such as:

- International network access: With dozens of branches and fabrication capabilities in three countries across two continents, SPI has what you need, where you need it, when you need it, no matter where your project is located.

- Strategic partnership: At SPI, we are more than just a distributor. We are here to be your strategic partner from start to finish, providing unbiased and practical assistance, logistical support, and so much more to help you get the job done right and on time.

- A commitment to quality: We're dedicated to fabricating and distributing high-quality commercial insulation products. By working with you and providing individualized attention, you get the solutions you need when you need them.

- A wide range of resources: Our team goes beyond knowledge. SPI provides industry education, advice, and updated industry information along with support staff.

- Personalized quotes: We know every job is different and we provide customized quotes that match your project's specification.

- Responsiveness: We'll work to understand your needs and deliver responsive solutions quickly, no matter the complexity. We strive to provide the best possible customer service experience for all our clients.

- Reliability: With decades of experience in the field, SPI has built a reputation for being knowledgeable, reliable, and action oriented.

- Expanded knowledge: Our expertise spans multiple industries, and we're ready to provide tailored solutions based on your requirements.

- Communication: From the first consultation to project completion, we maintain clear, open communication to address every detail.

- Safety: Since day one, we have maintained our commitment to safety as our top priority, with ongoing training, measurement, and communication. From loading materials at our warehouse to fabricating value-added products and delivering them to the job site, keeping our people safe is our highest consideration.

Leading the Way in Industrial Insulation Innovation

SPI is dedicated to pushing the boundaries of what's possible in the industrial insulation industry. We understand that innovation is key to meeting the evolving challenges of the industry, and we're committed to providing our customers with cutting-edge solutions that deliver superior performance and sustainability.

Staying Ahead with Insulation Trends and Sustainable Materials

SPI meets the evolving demands of the industrial sector with innovative and sustainable insulation solutions. We continuously research and incorporate the latest advancements in materials and technologies to help our clients achieve their goals for energy efficiency, carbon emissions reduction, and performance. From materials improvements to advanced application techniques, SPI is your partner in building a more sustainable future.

Contact SPI for Details About Industrial Insulation Products

Ready to enhance your facility with high-quality insulation? Explore SPI's full range of industrial insulation products today. With detailed product listings and technical information available on our website, you can make well-informed decisions about your project needs.

Contact SPI to discuss your requirements and get the materials you need to take your industrial projects to the next level.

.png)

.jpg)

.png)

.png)

.png)

.png)

(374 x 140 px) (1).png)

.png)

.png)

.png)